Get in touch

Frequently Asked

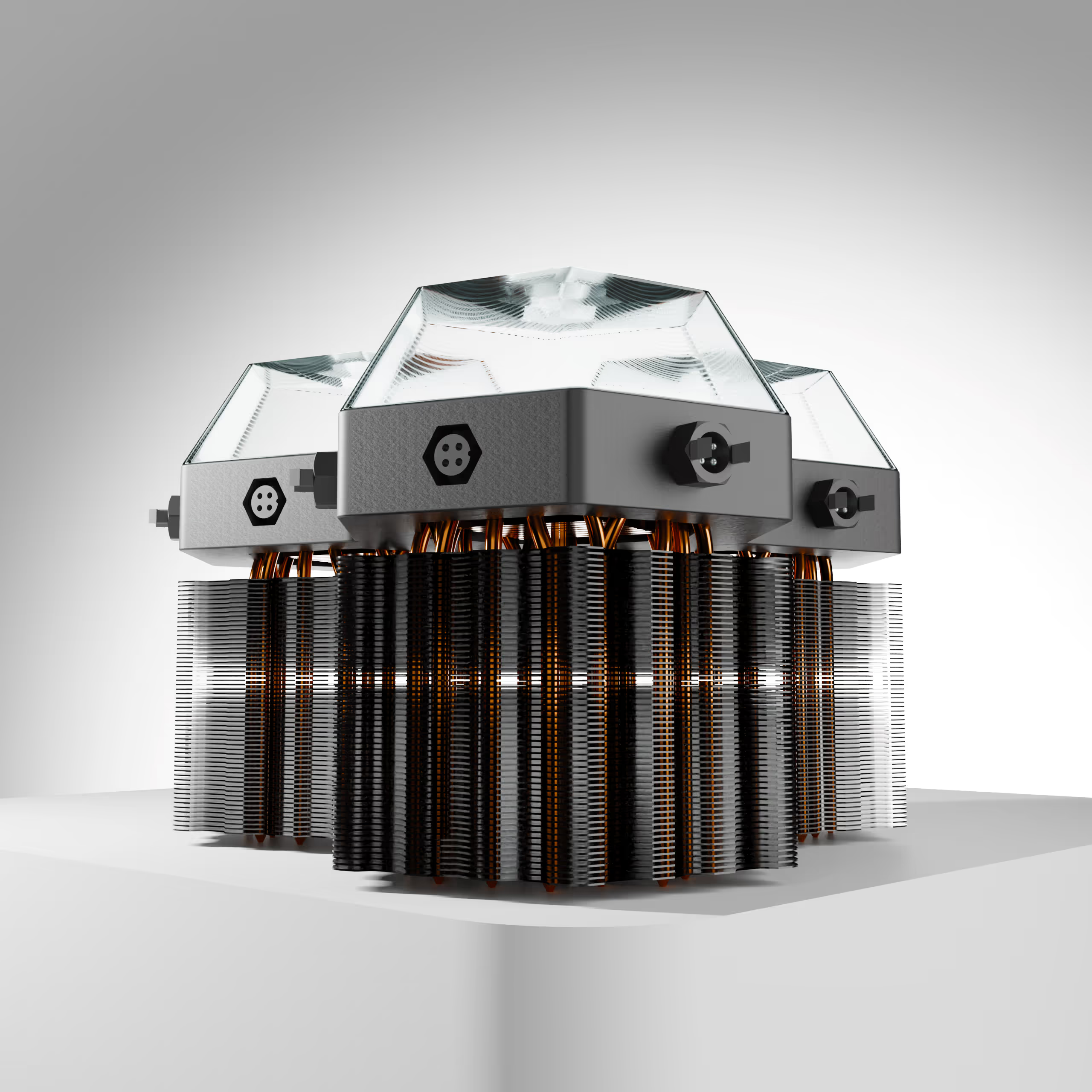

The Thermal Floater is designed for minimal maintenance. Regular inspections every 3-4 months are recommended to check for any debris accumulation or wear on the floating mechanism. The Fresnel lenses should be cleaned periodically to maintain optimal efficiency. In saltwater environments, anti-corrosion measures may need to be applied more frequently. Overall, the system is built to be robust and long-lasting, with most components having a lifespan of 20-25 years under normal operating conditions.

The Thermal Floater is engineered to withstand various extreme weather conditions. Its modular design allows for flexibility during high waves or storms, reducing stress on individual units. The system can be partially or fully submerged without damage. In areas prone to hurricanes or typhoons, an emergency submersion feature can be activated to protect the units. The Fresnel lenses are made of impact-resistant materials, and the entire structure is grounded to protect against lightning strikes.

We've conducted thorough environmental impact assessments to ensure the Thermal Floater's safety for aquatic ecosystems. The device is designed to minimize disruption to marine life and water quality. Its floating nature allows light penetration and doesn't significantly alter water temperature or composition. We continue to monitor long-term effects and collaborate with environmental experts to refine our design for ecosystem preservation.

The Thermal Floater's modular design allows for scalable installations tailored to specific energy needs and available water surface area. We offer customization options for different power outputs, ranging from small-scale residential use to large industrial applications. Our team works closely with clients to design optimal configurations that maximize energy generation while considering local environmental conditions and regulations.

We've designed the Thermal Floater to be compatible with existing power grids and energy systems. The device can be integrated into current infrastructure with minimal modifications. We provide technical support and consultation services to ensure smooth integration, helping clients navigate any regulatory requirements or technical challenges associated with connecting our system to their existing power networks.

We've implemented a comprehensive end-of-life recycling program for the Thermal Floater. Over 90% of the materials used in construction are recyclable. At the end of its operational life (typically 20-25 years), units are disassembled, with components sorted for recycling or repurposing. The thermoelectric modules contain valuable materials that are extracted and reused. Any non-recyclable components are disposed of responsibly.